Demand for data center capacity is literally unprecedented – set to grow 4 times more in the next 5 years as in the previous 25. So for general contractors, the pressure is on. With a new class of robotic equipment, data center GCs are building bigger, faster, and reducing labor risk.

In our latest video, we explore how:

Video

–

Demand is huge.

Data center GCs are at the epicenter of a technological sea change. The cloud is still growing. AI is booming. In 2025, total installed data center capacity was 60 GW. To meet demand, developers will have to build an additional 240 GWs of capacity in just five years.

But supply is constrained.

In Tier 1 markets, existing capacity is mostly gone. Average vacancy rates in the U.S. have fallen from 10% to 3% and in many markets, vacancy rates are around 1%. That means if capacity is going to be available in these markets, it has to be built. But, land and power constraints are delaying new builds. In Northern Virginia, for example, data centers face a 7-year wait to utility power interconnection.

So development is moving to smaller cities and rural areas. But there’s simply not enough construction talent in these small markets to meet the demand.

For example, Meta is building a 2-gigawatt data center campus in Monroe, Louisiana. The total population is just 46,000 and at least 5,000 construction workers are needed for Meta’s data center. As another example, Amazon is investing $10 billion in two data centers in Madison County, Mississippi. The total population there is just 109,145 and at least 7,000 construction workers are needed for Amazon’s data centers.

Hyperscalers face tough scrutiny.

Those aren’t the only challenges hyperscalers are facing. They’re also getting pushback from policymakers (the ones who control development permitting) and are under increased scrutiny for safety lapses. For the general contractors building hyperscale data centers, a perfect safety record is now a likely requirement.

These challenges present significant opportunities for forward-thinking general contractors.

The GCs that can meet unprecedented capacity demand, in new markets where talent pools are much smaller, to the highest quality and safety standards, will have a tremendous competitive advantage.

“The future of construction is being shaped by the integration of AI and robotics.”

– WTW

Drywall is key.

Drywall might not be top of mind. But it’s critical path for data center commissioning. So getting it done faster, even without large pools of skilled labor, is essential. Like excavators did for dirt moving, Canvas empowers workers with a new class of equipment that enables every worker to produce more.

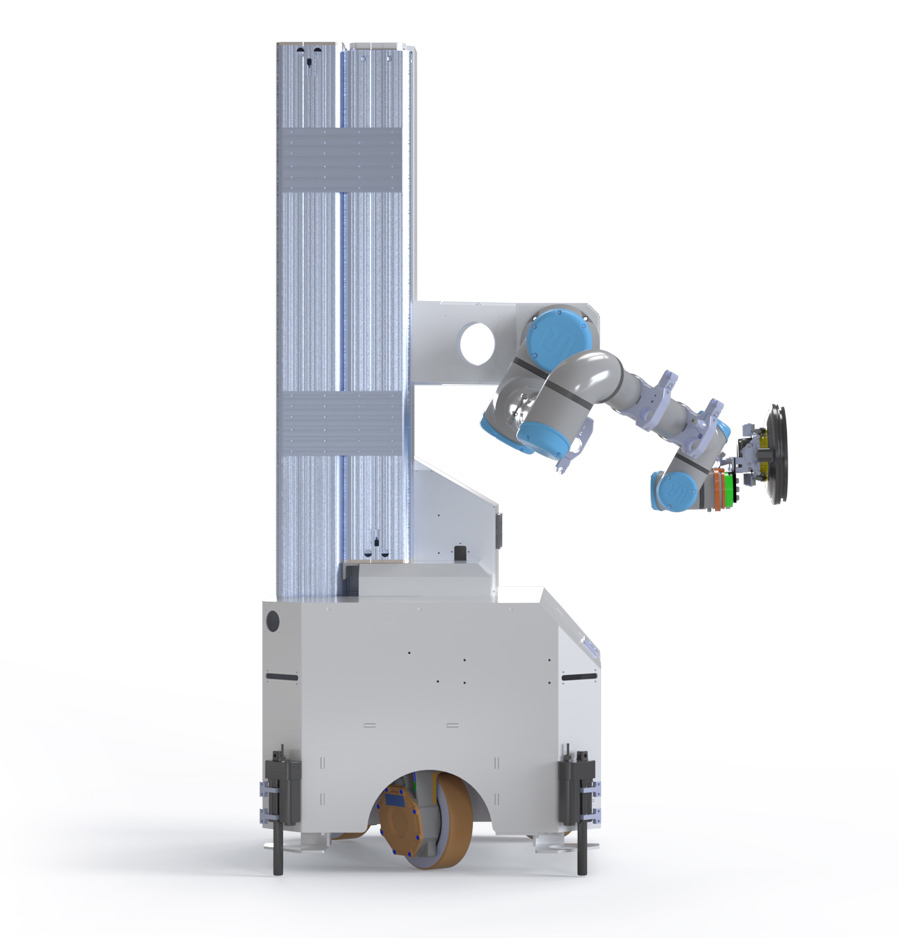

Demand is huge. Canvas helps GCs build more, faster. With an integrated 20-foot lift the robot can deliver speed at height while keeping workers safely on the ground. Providing rich data insights, Canvas enables GCs to identify bottlenecks and improve efficiency.

Supply is constrained. Canvas robots reduce labor risk. Our robots can be operated by workers with just a week of training. Setup takes just minutes, no plans or mapping needed. And with the robot’s ability to auto position, one worker can operate two machines.

Hyperscalers face tough scrutiny. Canvas robots help GCs build to the highest quality and safety standards. Our robots ensure quality by automatically calibrating to incoming conditions and compensating for any that are out of spec. They improve safety by taking on the most dangerous height work and repetitive tasks.

Now is the time to integrate drywall robots.

Forward-thinking GCs are leveraging robots to deliver in new markets, on time, on budget, and to the highest quality and safety standards. Canvas is a competitive advantage, and now is the time to harness it.

Learn more at the Data Center Hub

See for yourself how Canvas accelerates drywall finishing – even in markets where skilled labor is constrained, while maintaining rigorous standards of quality and safety