Data center general contractors are facing unprecedented pressure to build bigger, faster – and in new, labor-constrained markets. In Data Center Frontier, Canvas CEO Kevin Albert explains how construction robots can be a game-changing advantage for GCs. Get the highlights here, and read the full article in Data Center Frontier.

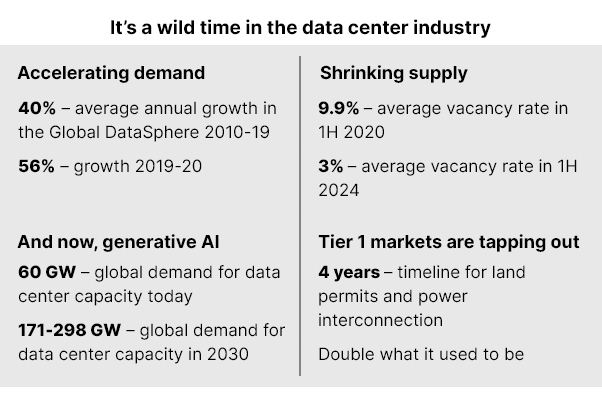

If you build data centers, you are at the epicenter of a technological sea change.

Driven by both AI and still-growing cloud demand, hyperscale development is expanding at a pace and scale never seen before – often outside Tier 1 markets, where skilled labor is hardest to find. GCs are expected to build 2-4x the capacity of the past 25 years…in the next five.

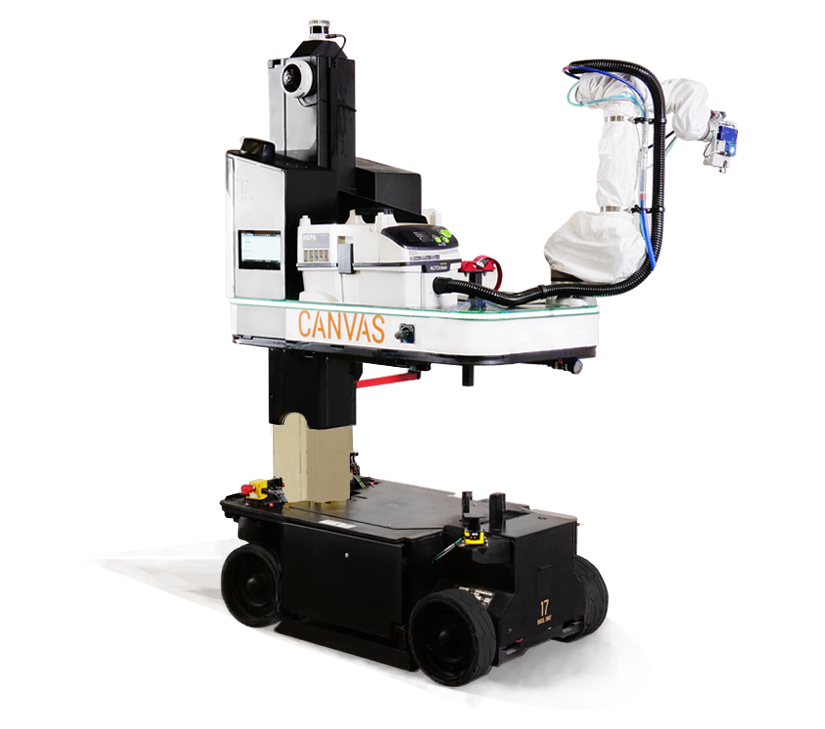

That kind of pressure demands new tools. Drywall might not be top of mind, but it is critical path for commissioning. So getting it done faster, even without large pools of skilled labor, is essential to delivering on time and on budget. That’s where drywall robots come in.

Drywall robots enable GCs to accelerate delivery and scale fast. Here’s how:

- With traditional methods, drywall production rates typically drop 50% above 10 feet. With an integrated 20-foot lift the robot can deliver speed at height while keeping workers safely on the ground.

- One worker can operate multiple robots, thanks to auto-positioning. Setup takes just minutes – no plans or mapping needed.

- Canvas robots capture accurate data on work performed, giving GCs valuable visibility to drive improved efficiency.

Drywall robots help GCs deliver even without a large skilled labor pool. Here’s how:

- New workers can be trained to operate robots in as little as a week, enabling fast ramp-up.

- Integrating robots into your workflow has the added benefit of expanding workers’ skill sets.

- Robots handle repetitive, high-precision tasks – freeing workers to focus on more complex jobs and attracting new talent.

Drywall robots ensure consistent quality and safety. Here’s how:

- Robots produce high-quality output consistently, regardless of the operator’s skill level.

- Detecting and compensating for out-of-spec conditions, robots help ensure accuracy and maximum uptime.

- With 20+ foot reach, the Canvas robot reduces the risk of falls – the #1 cause of jobsite injury – and helps prevent long-term musculoskeletal issues associated with repetitive motion.

Now is the time to build your competitive moat.

As WTW put it in its Q1 2025 Global Construction Rate Trend Report: “The future of construction is being shaped by the integration of AI and robotics.” Forward-thinking GCs can leverage drywall robots to meet project deadlines – especially for critical path work like drywall. It’s a competitive advantage, and now is the time to harness it.

For additional details, read the full article in Data Center Frontier.