Construction Robotics Startup Canvas Announces Public Launch: Startup empowering people to build in bold new ways launches with partnerships and $19M in financing

PRNewswire

Canvas, a construction robotics startup that is building the future in bold new ways, today announced its public launch and disclosed its participation in a number of high-profile projects as part of multi-year partnerships with leading construction developers, as well as its local painters union.

“We’re thrilled to announce our public launch and accelerate our vision to build in bold new ways,” said Kevin Albert, CEO and Co-founder of Canvas. “We’ve seen how fundamental transformation has come to other industries as robotics and digital tools become integrated into the work — as manufacturing incorporated industrial automation and logistics incorporated barcode readers and conveyors to pave the way for the ecommerce explosion. Until now, the equivalent innovation hasn’t been possible in construction due to the highly dynamic nature of the built environment. We’re excited that the Canvas system can play a key part in catalyzing this transformation in this vital industry.”

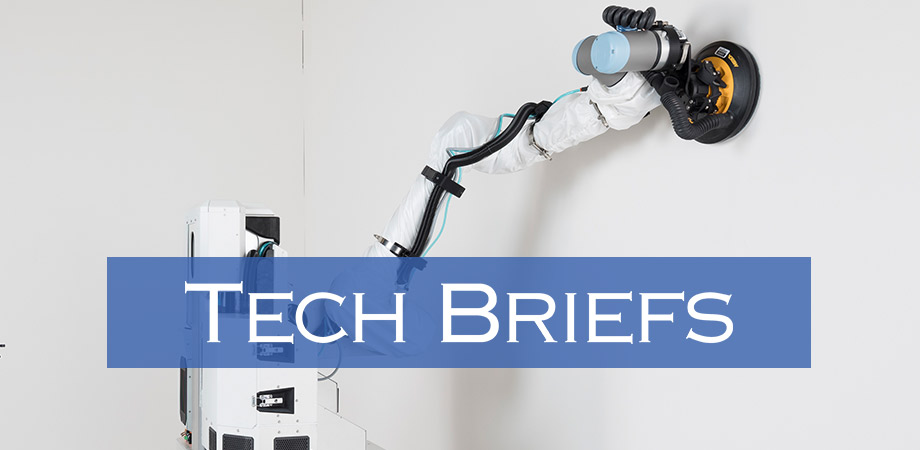

Canvas, headquartered in San Francisco and founded in 2017 by veterans of Boston Dynamics, MIT, and Stanford, leverages advancements in collaborative robotics and machine learning to build a new class of tool for the drywall finishing space. Formed as a spinoff of Otherlab, a privately held research lab, Canvas has raised $19 million to date from investors including Innovation Endeavors, Obvious Ventures, Brick & Mortar Ventures, and Grit Ventures. Canvas improves quality and safety by complementing the expertise and skills of union workers who operate the company’s tools on job sites. Canvas is a proud signatory to District Council 16 of the International Union of Painters and Allied Trades and trains and hires union workers for projects as a subcontractor.

As the business has prepared for national scale during its stealth period, Canvas crews have worked on a number of high-profile projects, including San Francisco International Airport Harvey Milk Terminal 1; the UCSF Wayne and Gladys Valley Center for Vision; and the global HQ at Chase Arena Towers for a tech client; in addition to several other projects for confidential Bay Area companies. The Canvas system consistently delivers better than Level 5 finishing, the industry hallmark of quality; reduces finishing times; provides a dust-free environment; and helps workers avoid many of the repetitive motions and height requirements that lead to injury.

“At Webcor, our goal is to deliver twice the value to our clients, and Canvas helps us do just that,” said Todd Mercer, Vice President of Webcor Builders. “We’re proud to be an early partner of Canvas, as their approach makes the job site safer — especially in the age of COVID — gives us unprecedented control over schedules by taking typical Level 5 finishing times down to 2 days, and produces high-quality results.”

For years, the construction industry has been experiencing major disruptions, including regulatory and safety pressures as well as skilled labor shortages — each of which have only been compounded by the response to COVID-19. Few industries have been deemed as essential as construction, yet working conditions across many sites make it difficult to maintain physical distancing and other safety guidelines while getting work done in a predictable and cost-effective manner. Construction has historically not been the focus for new tools or machinery — even as numerous advancements in robotics technology have been deployed across other industries, such as manufacturing, warehousing, and trucking — due to the complexity of the ever-changing job site environment. In the drywall finishing space, for example, skilled workers have relied on a standard toolbox that has remained virtually unchanged for decades, with significant ergonomic and safety implications. Studies have shown that drywall finishing and framing has the highest prevalence of work-related musculoskeletal disorder cases among such trades, with as many as 1 in 4 workers experiencing such effects.

“We’re excited that our partnership with Canvas has developed in the manner it has. It is creating meaningful Union career opportunities, helping introduce previously untapped communities to the trades, and making the work itself safer and reducing the strain on the body,” said District Council 16 Business Manager, Robert Williams III, a third-generation Union painter. “It’s critical for skilled workers to have great resources in their tool kit, and we are excited to be on the leading-edge of technology in our industries by partnering with Canvas.”

The Canvas system represents a bold new way to build and a first glimpse into the future of construction.

###