Bouma Corp. Inks Contract with Canvas for Multiple Drywall Finishing Robots: Innovative architectural finishes company is 1st in midwest to begin deploying the machines

Construction Dive

When it comes to strengthening your business, the old rules no longer apply. “You can’t use integrity. You can’t use quality. You can’t use on-time. Those are just permission to play,” says Andrew Rener, President of The Bouma Corp., a Grand Rapids, Michigan-based interior and exterior finishes firm. “Our goal at Bouma is to leverage new technologies and systems that contribute to Bouma’s success, while benefiting our people who do the work.”

Making projects more productive and efficient is one of the main reasons Rener advocated for Bouma to sign a multi-year/multi-machine contract with Canvas to lease the company’s drywall finishing robots.

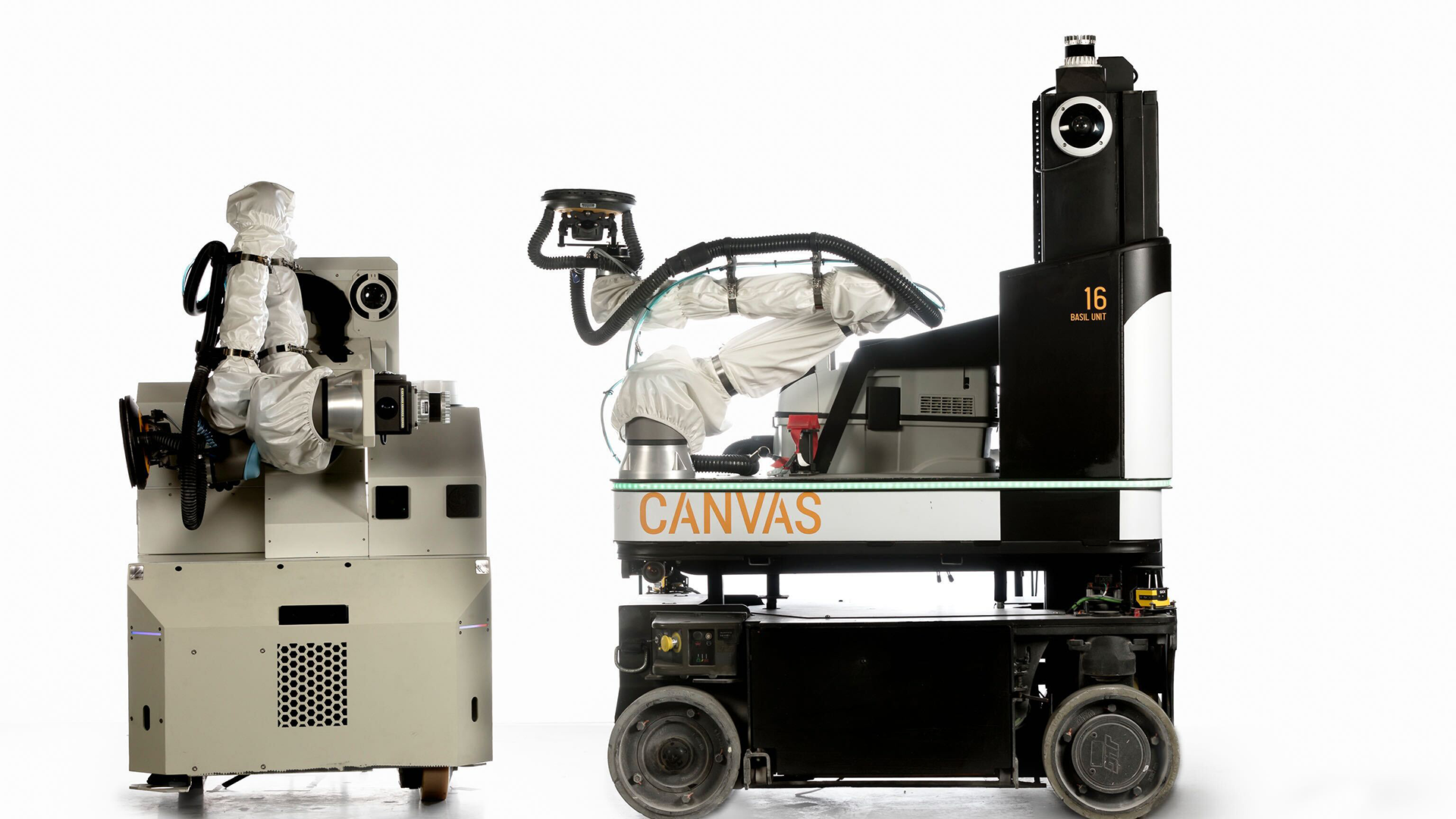

Worker-operated Canvas machines are kitted with a robotic arm that sprays finely calibrated applications of joint compound to either Level 5 or Level 4 walls. In Level 5 mode, the machine sprays the entire wall. In Level 4 mode, it sprays only the drywall section seams. After one dry cycle the walls are ready for sanding. This radical new way to mud drywall is a “one and done” system that requires one application of mud, one dry cycle, and one sand cycle versus the multiple mud/dry/sand cycles required by the traditional method.

The Canvas machine can also sand Level 5 walls by changing the end-effector on the robotic arm from a sprayer to an orbital sanding head, which also vacuum captures 99.9% of the dust produced by sanding. For both mudding and sanding, the arm can telescope to reach heights as high as 15.5 feet.

Rener makes it clear that while he is deeply interested in unlocking new schedule and budget efficiencies on Bouma projects by using the newly leased Canvas machines, he also believes the Canvas System has the power to attract new people to the trade and to keep Bouma’s current tapers safer, happier and in their jobs longer–which will help Bouma execute more work.

“One of the reasons I’m interested in the machine is its ability to draw people into the construction industry who otherwise wouldn’t be interested,” Rener says. He explains that people see work in the drywall trade as hard physical labor that can be dangerous, making it difficult to attract new people and to retain current employees. Canvas minimizes worker fatigue and injury by doing all of the post-tape mudding and (in Level 5) a majority of the sanding. “The Canvas machine makes this tough job more ergonomically safe. That was a huge selling point for us,” Rener says.

Canvas has also “gamified” the work, he adds, by providing workers with a game-like tablet that young people are familiar with, making it much more attractive to a whole generation of potential workers. Will some workers miss doing a large portion of a project’s mudding or sanding? “Only because they are not familiar with different approaches and because their body can still do it,” Rener says. “Take a guy who’s in his mid-fifties and wants to work another 10 years but his shoulders or back won’t do it. If he’s willing to learn, we will help him stay in the workforce longer by giving him a tool that will reduce fatigue on his body.”

Rener, who is passionate about the evolution of the construction industry through the incorporation of technology and modern construction methods, says the company is excited to be the first drywall finishing contractor in the heart of the country to deploy the Canvas robots. Bouma recently trained on the Canvas machines and will soon deploy them on multiple projects.

“We are thrilled with the partnership between Bouma and Canvas,” says Canvas Chief Revenue Officer Chris Peterson. “Bouma has been on the ENR Top 600 Specialty Contractors for multiple years in a row now, so they clearly have a strong pipeline and can maximize their use of our machines. Bouma and Canvas also share a common belief in our system’s potential to attract new workers and to protect currently employed trade workers. Canvas puts the machine in harm’s way instead of Bouma’s most valuable asset–its workforce–and it offers an exciting new opportunity for the company to reach out to a group of workers who may have previously overlooked drywall finishing as a career. We are excited to see where this partnership leads.”

###