Drywall contractors that can help build data centers fast, and at scale, have a unique opportunity to drive a competitive advantage. In Walls & Ceilings, Canvas CEO Kevin Albert explains why robots are key to achieving that competitive edge. Get the article highlights here, and read the full article in Walls & Ceilings.

It’s a good time to be a drywall contractor in the data center industry.

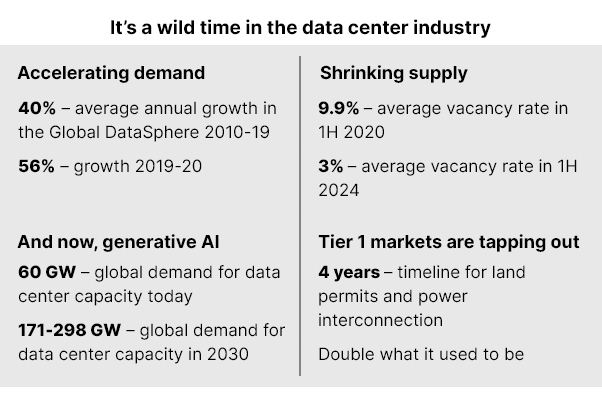

Drywall is critical path for GCs, who are under tremendous pressure to build 2-4 times as much data center capacity in the next five years as in the previous 25.

Challenges abound: More new development is occurring in smaller cities and rural areas, where skilled labor is even harder to come by. At the same time, tech companies face ever-more scrutiny about the impact of their data centers, so have no tolerance for safety lapses.

Drywall contractors that can build fast, at scale – and do it on budget to the highest quality standards – have a unique opportunity for a competitive advantage. These are the kinds of campus-level contracts that can enable game-changing scale for your business.

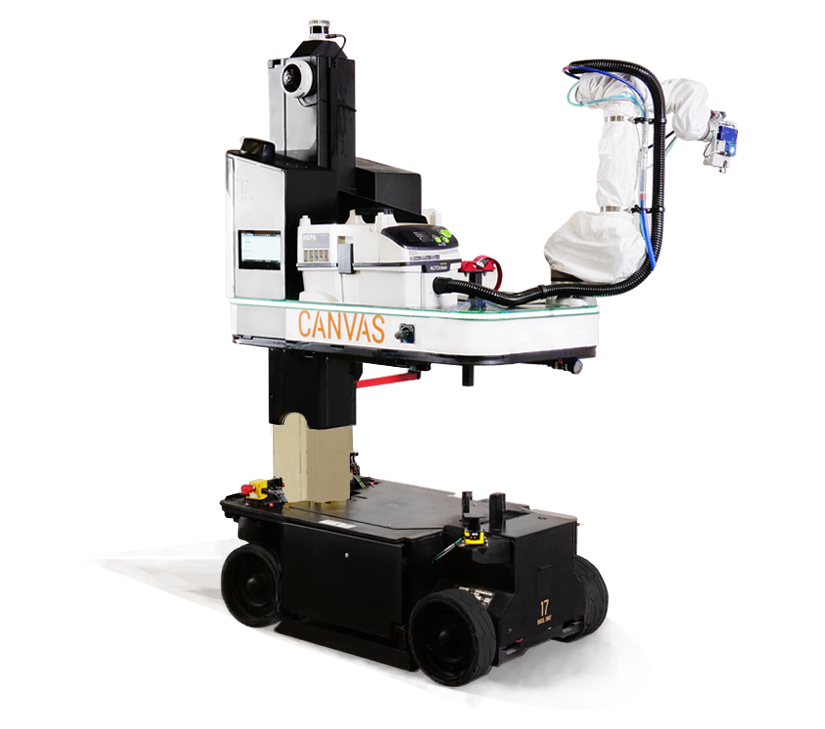

Drywall robots enable you to accelerate delivery and become a hero. Here’s how:

- Set-up and operation is easy. Operators can be trained in as little as a week. The robot can be set up within minutes on any site – no plans or mapping needed.

- Drywall production rates with traditional methods are typically 50% lower above 10 feet. With an integrated 20-foot lift, the Canvas robot is 100% productive at any height.

- Auto-positioning enables one worker to operate two robots. The operator sets the target finish, reviews the plan, and can then move on to parallel tasks.

Drywall robots enable you to ensure the highest levels of quality and safety – critical when timelines are tight and tolerances are shrinking. Here’s how:

- Canvas robots detect and automatically calibrate to incoming conditions, compensating for any conditions that are out of spec, while ensuring accuracy and maximum uptime.

- Because falls are the leading cause of construction injuries, drywall robots with a 20+ foot reach improve jobsite safety. They also prevent chronic injuries associated with repetitive motion and prolong workers’ careers.

Drywall robots enable you to grow fast, without the risk. Here’s how:

- If you’re turning down projects right now because you can’t find skilled workers, integrating drywall robots can enable you to expand – and mitigates the significant risk that skilled labor shortages impede your ability to deliver on time.

- Integrating drywall robots into your workflows can also make your growth more sustainable for the long-term, even as the labor market continues to change.

Build yourself a competitive moat.

While drywall robots can be integrated quickly and easily, becoming really good with robots as an organization is a skill that has to be developed. The contractors doing it now are getting ahead of competitors by building a culture designed to reap the rewards of technological advancements in robotics and AI – today’s, and tomorrow’s.

For additional details, read the full article in Walls & Ceilings.